Accutech Process Weighing

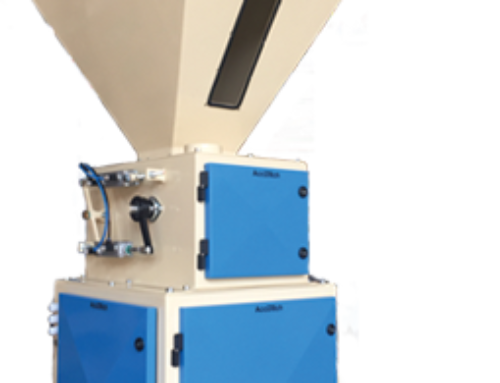

All Accutech Process Weighers include an AT-30 Processor Controller, which may be mounted remotely if required. The weigh hopper is suspended from two load cells and has a stabilizing mechanism to prevent movement during filling. Retractable calibration brackets are provided on the weigh hopper for ease of calibration.

Application

Tailored for milling, silos, vessels, trains, ports, and any industrial setting demanding higher precision than a weigh bridge for weighing purposes.

Features

Optional Extras

How it works:

The material enters the scale through the open inlet feed gate and is accumulated in the weigh hopper until a preset weight is reached.

The inlet gate then closes and a short time period is allowed for the material to settle before the gross weight signal is read and recorded by the controller.

The discharge gate is then opened and the material is discharged. The discharge gate is then closed.

The controller reads the tare weight value and subtracts this from the gross weight value. The true nett weight is added to the scale total. This cycle is then repeated.

Process Weigher Chart Capacity

NOTE:

CAPACITIES FOR AC30,AC60,AC90 & AC120 BASED ON 5 TIPS/MIN.

CAPACITIES FOR ALL OTHER SCALES BASED ON 4 TIPS/MIN.

FOR AC200 THE FIGURES IN BRACKETS ARE BASED ON 5 TIPS/MIN AND ARE ONLY TO BE USED FOR FREE FLOWING PRODUCTS AFTER CONSULTATION WITH TECHNICAL DEPARTMENT

Technical Data

Typical Equipment Dimensions – TBC

Air Consumption – 40nl/m Clean Dry Air

Electrical Requirements – Input Voltage 110V AC-60Hz or 220V AC-50Hz

Power Consumption – 50W

Operator Pressure – 6-Bar -90PSI

Ambient Temperature – -5°C – 48°C

Powder Coated Colors -Machine-Carrier Beige – Doors – RAL 5012 (others Optional)

Process Weighing Spares

[fusion_products_slider picture_size="fixed" cat_slug="at-30" number_posts="4" carousel_layout="title_below_image" autoplay="yes" columns="5" show_nav="yes" mouse_scroll="no" show_cats="no" show_price="no" show_buttons="yes" hide_on_mobile="small-visibility,medium-visibility,large-visibility" /]