AeroLIft, Gorbel, Track-O

We work in partnership with global companies whose products compliment our own materials handling solutions. If you have a product you believe would work in line with our range of equipment, contact us now.

Track-O

The Track-O is operated by remote control. This means you do not touch the machine or the load while it is moving. This makes the Track-O safer than any other motorized hand truck, appliance hand truck, or stair climbing moving machine.

The Track-O is a safe, versatile, rugged and reliable alternative in material handling and lift equipment. The result is fewer injuries, less property damage, and lower costs. Eliminate the safety risks involved in moving heavy equipment on stairs with a Track-O.

The Track-O is very easy to operate and requires very little operator training. The remote control operates the same way whether you use the Track-O as a stairclimber or an all-terrain dolly. Unlike hand trucks or other moving equipment, the Track-O requires no physical effort by the operator. Operated by remote control, the Track-O virtually eliminates the chances of personal injury.

BalanceLift

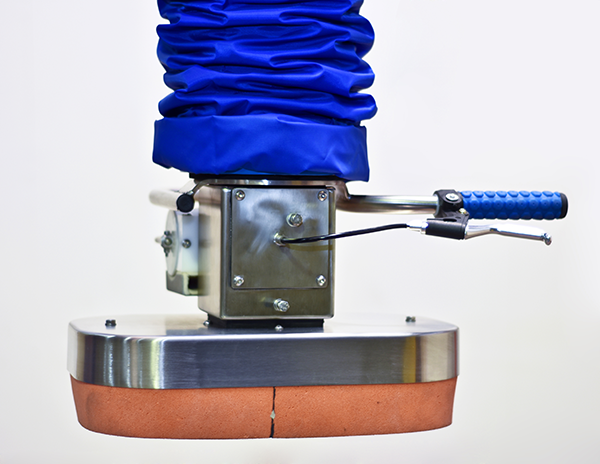

Pneumatic lifting Cylinder for Ergonomic Load Handling

Loads that previously could only be handled with expensive accessories can now be handled efficiently and ergonomically with the BalanceLift pneumatic vacuum lifter. Thanks to the BalanceLift the operator always maintains an optimal and ergonomic posture when lifting and moving loads of up to 150kg.

The Solution for Effortless Lifting

BalanceLift provides effortless load handling without electric power. An enormous range of vacuum, pneumatic, magnetic, and mechanical load handling attachments and gripping devices offers application- oriented solutions for handling the most varied goods weighing up to 150kg, and with lifting heights up to 4 m. Simple, continuous and precise manoeuvrability via up/down controls or with the balancer function (without control buttons – the load is balanced automatically). In this way, the operator always has perfect control of the load – without any physical effort, and with natural working movements. This increases productivity, and contributes towards maintaining employee health. Load handling is pneumatic, i.e. without a connection to electric power. All that is needed is a compressed air supply (6 bar). Because compressed air is only required for lifting, this type of energy supply is extremely cost effective. Moreover, the BalanceLift offers flexible mounting options: In combination with BalanceRail overhead rails, floor or wall mounted crane booms, with the mobile BalanceStand or BalancePort, or mounted in existing customer installations, the BalanceLift system optimizes the necessary handling tasks at the workplace.

In close cooperation with the end user, our experts design and build customer-specific vacuum, pneumatic, magnetic, and mechanical load handling attachments. Palamatic‘s handling consultants first examine and discuss the task on your premises, and then prepare an individual handling analysis. Within a few days, you will receive a detailed offer for the corresponding handling concept.

Gorbel

| The Gorbel range of intelligent lifting devices have been deisgned to lift and manouver naturally as if the devices were an extension of an operators arm. |

- Capacities from 165 to 1320 lbs.

- Speeds up to 200 ft. per minute

- Can cover multiple work cells

- Rapid return on investment through increased productivity and reduced product damage

- Decreases risk of operator injury creating a safer work environment

- Higher environmental ratings (more tolerant to dust and liquid)

- Enhances job performance

- Plastic and Paper Sack Lifting

- Burlap, Hessian and Polywoven Sack Lifting

- Bag/ Liner Lifting using Hook or Gripper

- Sack and Box Lifting on the same Processing Line

- Stainless Steel Sack Lifting Systems for Sanitary Areas

- One handed options

Safety

- Virtually eliminates the risk of personal injury and property damage

- Operator does not need touch the load during handling (operated by easy to use finger-tip controls)

- Minimal physical effort is required to lift and transport payload

- Reduce risk of injuries to the operator commonly associated with manual handling

- Reduce absenteeism caused by injury sustained during manual handling

- Reduce risk of costly insurance claim against organisation through an injury received during manual handling

Reliable and Rugged

- Alternative power options available (electrical or air)

- Built to work and last

- Low maintenance and servicing costs

- For many applications, one single maintenance check-up per year is required

- Versatile; works on uneven surfaces, inclines, porous objects and so on…

- Increase overall product throughput

- Powered by 3ph 300 – 415v 50Hz and/or 3ph 380 – 480 60Hz

- Compact enough to fit in restricted access environments

- Turn on vacuum pump using starter isolator (see options)

- Grip control handle and operate raise action via control lever to lift unit

- Walk over to product stack using free movement of support gantry

- Use control lever to lower and position tooling onto the centre of gravity of the load

- Use control lever to raise load away from original location

- Walk over to destination location using free movement of gantry

- Position load onto position